Dental Milling Machine

A milling machine that processes tooth fillings. It was developed by applying the technology and experience cultivated in “Compact 3D machining center” to dentistry.

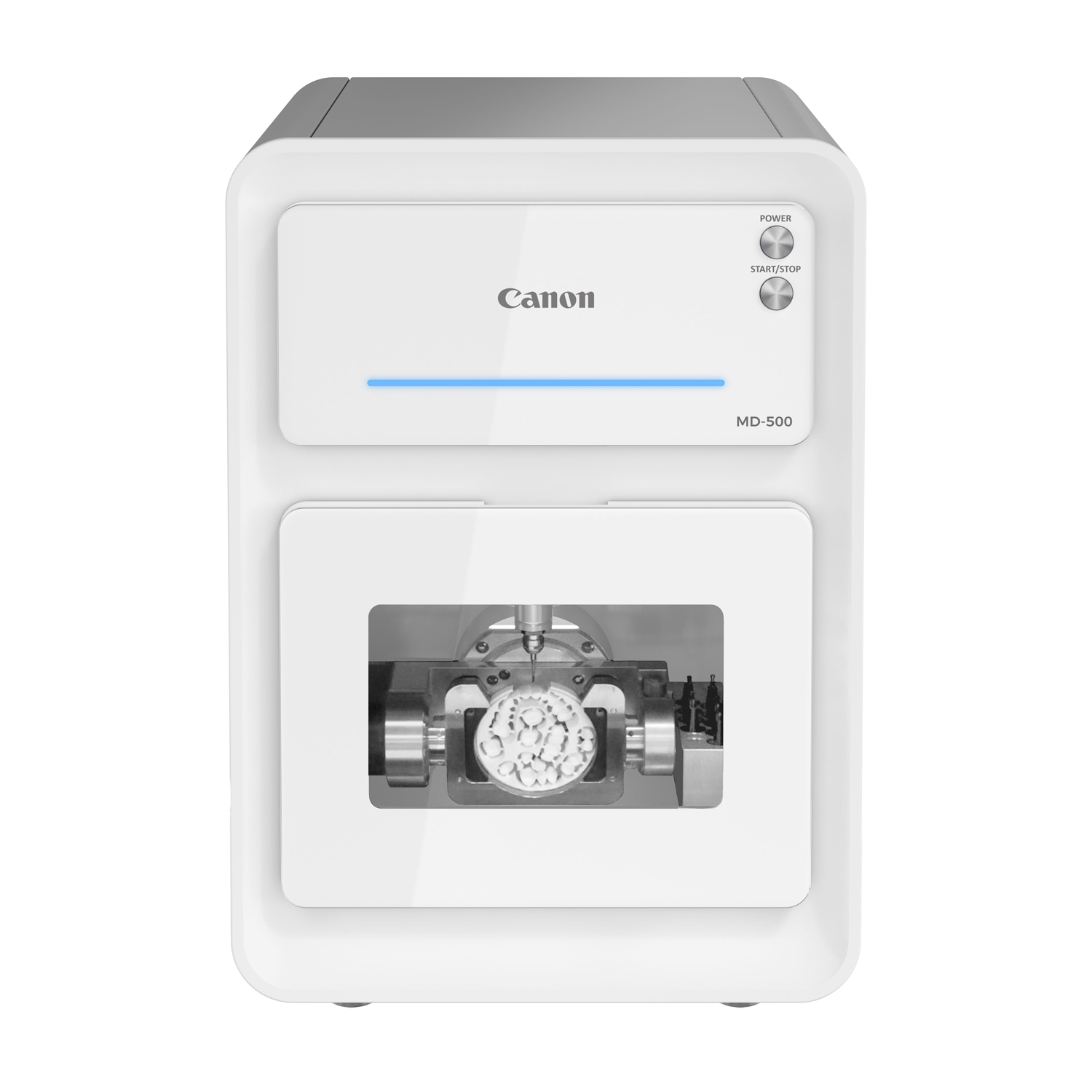

MD-500

Five-axis controlled milling machine based on industrial manufacturing products, it assures high-speed and highly accurate machining.

Confirm your status.

Are you a medical professional?

Our website content that you have accessed to includes the information of PMD Act for medical professionals. This is on closed access except for the medical professionals.

※ If you are not the medical professional, back to our website’s homepage automatically.

- High rigidity

-

A single frame base with the X, Y, and Z axes provides high rigidity.

A combination of spindle with the fixed holder minimized fluctuation at the drill tip.

Linear guides and ball screws enable precise positioning and stable milling. - No calibration required

-

High accuracy linear guides and ball screws for the X, Y, and Z axes and high accuracy decelerators for the A and B axes contribute to the reduction of displacement; as a result, no calibration is needed.

- Highly accurate milling

-

Highly accurate milling makes margin lines thin. It significantly reduces the operation time required for hand finishing by a dental technician.

- Holder chuck system for high gripping force

-

A milling tool is secured by holder chuck system with a nut for high gripping force. This chuck system also reduces vibration from tool rotation, resulted in highly accurate milling.

- Compatible with a zirconia disc and blocks

-

Various sizes of a zirconia disc/blocks up to 12 can be milled with a dedicated jig to maximize milling efficiency.

The C-shaped clamp is a disc frame holder having an opening. From the opening, the milling tool can directly process the interproximal area of frontal teeth, which improves more esthetic appearance. - Automatic Tool Changer (ATC)

-

MD-500 equips ATC which changes 10 milling tools automatically. It makes smooth transition between different milling tasks.

- Stylish design

-

A large LED indicator and transparent window visualize work in progress. Stylish white and silver color of the machine enhance the beauty of the interior of dental laboratory.

(Winning 2019 GOOD DESIGN BEST 100 award in Japan, and iF DESIGN AWARD 2021 in Germany) - Original control application (md-gear)

-

The original application (md-gear) can provide a user-friendly screen on a computer display, which meets the various needs of dental laboratories such as rearranging the milling orders and extracting unfinished work.

- Specifications

-

MD-500

Installation/operation conditions Indoor (no vibrations)

Room temperature: 0℃ to 40℃ (32℉ to 104℉)

Humidity: 20 to 75% RH (no condensation)Milling conditions Dry milling Dimensions 500 mm (W) x 740 mm (D) x 680 mm (H) Excluding adjuster Main unit weight 110 kg Number of control axes 5 (X, Y, Z, A, and B) A/B-axis range A-axis: ±360°, B-axis: ±30° Millable material Zirconia, Wax, PMMA, PEEK, Hybrid Resin Compatible blocks Blocks for dental milling Universal type (Dia 6mm) Maximum number of blocks 12 Maximum block dimensions 15 mm x 15 mm x 18 mm (when using 12 blocks) Maximum block length 85 mm Compatible discs Discs for dental milling Disc dimensions 98.5 mm (diameter) x 10 to 35 mm (thickness) Spindle Rotation speed 5,000 to 60,000 rpm Output power 0.35 kW Cooling system Air cooling ATC Clamping method Holder chuck type Milling bur length 45 to 60 mm Shank diameter 4 mm, 6 mm Milling tool storage count 10 Feed speeds Cutting feedrate Maximum: 5 m/min (X, Y, and Z axis)

Rapid traverse Maximum: 15 m/min (X, Y, and Z axis)Utilities Power supply 220 VAC, 8 A 100 VAC, 15 A Air Air pressure: 0.6 to 0.7 MPa, Air ow: 60 L/min

Connection port: Dia. 6 mm air tube

Remove foreign material and moisture using a filter and air dryer.※The specifications described are subject to change without notice for improvement.

- Instruction manual

-

Please refer to the “Instruction manual” for details.

- Cleaning guide

-

Please refer to the “Cleaning guide” for details.

- How to resolve the error message

-

Please refer to the “Solutions to errors and problems” for details.